Technology

|

|

TECHNOLOGIES INNOVATIONSGERMAN ENGINEERINGIt all starts with an idea, a mental concept or a vision - inspired by the knowledge of what motivates bikers, what fascinates them and what ultimately makes sense, is useful and innovative. This is followed by meticulous work on the project – the search for and discarding of solutions, and starting again from scratch with a new approach. The results continually have to be measured against the objectives. Our engineers are untiring in their efforts of searching for creative solutions and coming up with improvements that make technical sense. A wide range of technologies that make our frames and components the best in the world have been created this way. All the development steps take place at our headquarters in Idstein and all ideas, new developments and research projects are initiated, managed, coordinated and reviewed in Germany. Before going into production, every product is tested by means of scientific methods and on our own test benches. German Engineering is an attribute of all Storck products – an attribute we are proud of and that our customers can rely on. The approaches of our engineers pursue a single aim: to develop frames and components with outstanding technical features. Read on to find out what technologies abbreviations such as DDS, TFA or PPT stand for. |

|

| DDS -Directional depending stiffness | |

| Directional depending stiffness is the ability of a frame or component to optimally respond with high stiffness to the forces acting in the load direction while ensuring high comfort. In other words, it is the synergy between intended stiffness and desired comfort. In the case of frames, this is achieved by designing transverse-oval tube shapes, the targeted selection of materials (e.g. carbon fibers) and their application (e.g. special layups for carbon fiber reinforced plastics) |  |

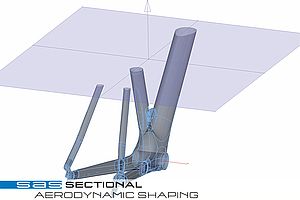

| SAS - Sectional Aerodynamic shaping | |

| The rider and his/her seating position essentially determine the aerodynamics of the total system. The geometry of the bike (handlebars, wheels, frame) is another factor. For the frame, the frontal areas opposing the airflow need to be minimized to improve the drag coefficient of the total system. It has been proven that a drop with 0.02 has the optimal drag coefficient. Therefore, Storck frames with SAS have a natural drop shape in ground parallel aerodynamics: less loss of force due to more aerodynamics. |  |

| HFX - Hysteresis Flex | |

| Damping without dampers. When an effect lags behind the variable force that causes it, this is called hysteresis. Storck handlebars, seat posts and frames exhibit this special characteristic. Its secret lies in the processing of the CFRP materials. Specifically, we are talking about layups in this context. Shocks can be optimally absorbed this way. ‘Bouncing’ is minimized and the original state restored faster. Ultimately, this means more control for the rider, less loss of force and higher comfort. |  |

| AAS - Advanced Sectional Aerodynamics | |

| The ideal drop shape makes it possible to achieve an engineered optimum of the drag coefficient just by using SAS technology. In AAS, the basic idea of “Ground Parallel Aerodynamics” and the resultant optimization of the cwA value are complemented by the introduction of a trailing edge that dissolves vortices. Better aerodynamics combined with enhanced material efficiency due to purposeful further development of the tube construction. |  |

| ILS - Infinity Loop Stay | |

| Seat stays as damping elements. A curved stay with a very large radius offers enormous damping without sacrificing stiffness or adding weight, which must be accepted for spring elements. The preformed seat stay absorbs shocks and bumps. Ideal in combination with HFX. The results are noticeable gains in comfort and higher riding safety resulting from increased traction. |  |

| ISM - Integrated Seatpost Mount | |

| The integrated seat clamp results in the seat post offering longer spring deflection due to the elimination of the seat mast on the frame, which automatically increases the flex of the seat post. This effect is supported by HFX in our MLP seat posts. The longer the extension of the seat post, the greater the effects of these properties. In addition, ISM impresses with an uncluttered look and weight savings (shorter seat tube, elimination of the seat clamp). |  |

| FSI - Flat Section Impact | |

| The second area moment determines the behavior of a component under bending and torsional loads depending on the loaded cross-sections. The partial reduction of the axial second area moment of the Fascenario.3 seat post improves hysteresis flex behavior combined with stable torsion stiffness and a positive aerodynamic effect: AAS. This results in enhanced comfort and aerodynamics in the area of the rear triangle / seat post |  |

| PPT - Proportional Tubing | |

| Larger frames, due to the rider’s weight and higher leverage, are naturally exposed to higher load changes as well. Proportional Tubing takes these loads into account. The conification, the wall thickness of the tubes and the diameter are adapted to these loads. This results in frames which, irrespective of the frame height, deliver consistently good stiffness and comfort values. |  |

| IBS - Integrated Brake System | |

| Bicycle system integrations are an important approach to achieving further optimizations in bicycle technology. Integrated brakes have the advantage of being perfectly adapted to the relevant frame in terms of function and form. Properly used and positioned, IBS provides improved brake performance, higher aerodynamics and noticeable weight savings. Visually, the overall impression of a frame can be upgraded by integrated brakes as well. |  |

| TFA - Torque Free Axle | |

| Disc brakes massively stress the frame and the axles due to the absorption of the torsion and shear forces that are generated while braking. Torsion-resistant shafts, called through-axles, are the best way to counter these forces. Storck through-axles are not only used in mountain bikes but have long made their way into cross and road bikes with disc brakes as well. They provide stability, precise fit and stiffness. |  |

| PFB - PressFit Bottom Bracket | |

| Press-fit bottom brackets have a number of advantages. There are no threads that might wear and make disassembly work more difficult. PressFit technology uses clearly less material and thus saves weight compared with conventional technologies. The greater bottom bracket widths provide even higher stiffness in this area and, ultimately, allow larger tire clearance. In addition, press-fit bottom brackets can compensate for technique-related manufacturing tolerances incurred with anisotropic materials (CFRP). |  |

| ODM - Optional Direct Mount | |

| The selection of shifting variants for off-road assemblies is very large. Opting for a triple, double or single chain ring is a completely individual choice. Those selecting a single chain ring can dismantle the front derailleur mount and give the frame an uncluttered look that is undisturbed by a superfluous assembly platform. The frame can just as quickly be prepared again for a multiple chain ring: a minor detail with a major impact. |  |

| T25 - On The Fly Maintenance | |

| Never again without tools out in the middle of nowhere. A tool for (nearly) all bike purposes that doesn’t require a tool bag. The T25 standard torque wrench unobtrusively and securely fits in the through-axle drill hole, for example, always close at hand. As a result, monolink seat posts, stems, through-axles, head set clamps, disc brake mounts, ODM and bottle holders on a Storck can all be installed with the universal wrench. |  |

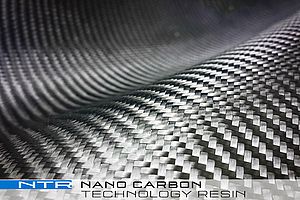

| NTR - Nano Carbon Technology Resin | |

| If the surface properties of the particles instead of the volume properties determine the quality of the material this is referred to as size-induced functionality. The utilization of nanoparticles in the resin structures of the carbon fibers improves the breaking and splintering behavior and increases the flexibility of the component as well. Enhanced comfort combined with higher component safety. |  |

| OFD - Optimized Aero Fork Design | |

| The optimum distance between components prevents aerodynamically unfavorable vortices of the airflow. The open and wide design of the Fascenario.3 fork takes this into account and thus avoids the resistance and its braking effect that might occur due to air stream vortices between the fork and the wheel in a design where the components are too close together. This approach is supported by the aerodynamically favorable seat of the fork crown on the head tube. |  |